Metal fencing manufacturing techniques

Nov 01, 2018

Metal fences manufacturing

The manufacture of metal fences is a complex technological process that requires precise compliance with the established parameters.

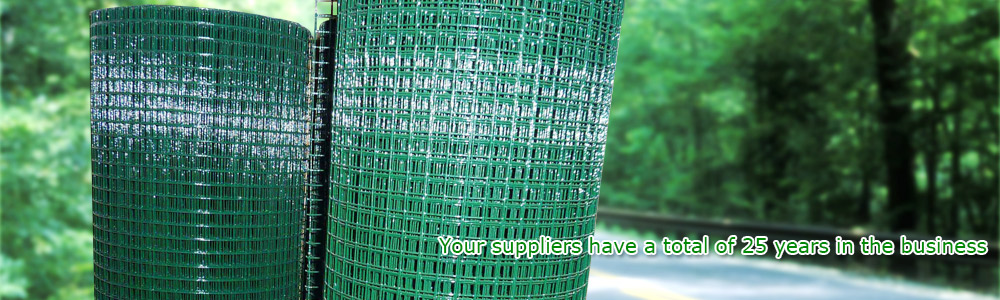

In the production of fences, universal computerized welding machines, pipes and sheet-rolling equipment, wire bending machines, laser and other equipment are used.

The use of this high-tech equipment allows to produce more than six thousand types of welded meshes for metal fences as quickly and as efficiently as possible. All operations are automated, which allows to produce large volumes of products with consistently high quality.

Manufacturing of metal fences according to modern standards

All work is carried out in factories with modern equipment in compliance with all norms and requirements, all metal fences meet GOST quality standards and European standards. Due to this, all products are given a warranty period of 5 years, and the actual lifetime of the fences is 30 years.

Factors such as versatility and optimal design solutions are always taken into account. You can always order and install additional accessories to improve the safety of the fences, and the equipment is designed so that the installation of metal fences is carried out without additional labor costs and special skills and knowledge.

Stages of production of fences

The process includes several main stages:

- production of pillars, fasteners, nets for the fence;

- painting of finished products;

- packaging.

Poles and fasteners

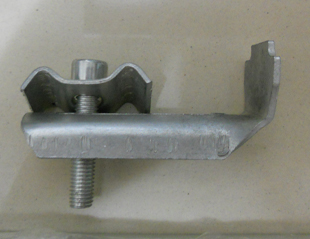

One of the main stages is the production of metal fence posts, because the whole construction of the protective system rests on them. For them, galvanized sheet steel with a thickness of 1.6-2 mm is used. A twisted square or rectangular tube of 40x60 mm is twisted from it. Depending on the purpose of fencing, the wall thickness of the pipes may be different. To protect against corrosion, they are coated with hot zinc. Inside the pipes there are holes for rivet fasteners.

Metal fences manufacturing. Also, one of the important elements is fasteners, which allow to connect the individual elements of the metal fence system with high quality and reliable. Galvanized steel with a thickness of 3 mm is used for fasteners. A sheet of metal is cut into blanks using a laser, and then subjected to stamping.

Painting finished fences

At the final stage, fences and fences are painted to give them an aesthetic appearance. We use modern paints and application technologies that make it possible to give all products an attractive look and ensure a long service life - up to 30 years The process of painting finished fences is carried out in stages, it includes the following operations:

- removal of scale and grease;

- washing with special compositions;

- painting and coating formation in the furnace;

- cooling products.

Containment Systems Packaging

At the last stage of the technological process, metal fences in sections are placed on a pallet. To further strengthen the packaging, the corners of the pallet are reinforced with wooden bars and plates. This helps prevent damage to parts of the fence during transportation and unloading.

The wooden/steel pallet for packing the pillars is additionally supplied with side holders. To prevent deformation, the posts are rigidly fixed with tape.

The company YOUDA offers to buy a metal fence in a wide range, which you can buy at the factory prices.

Previous: None

Next: None